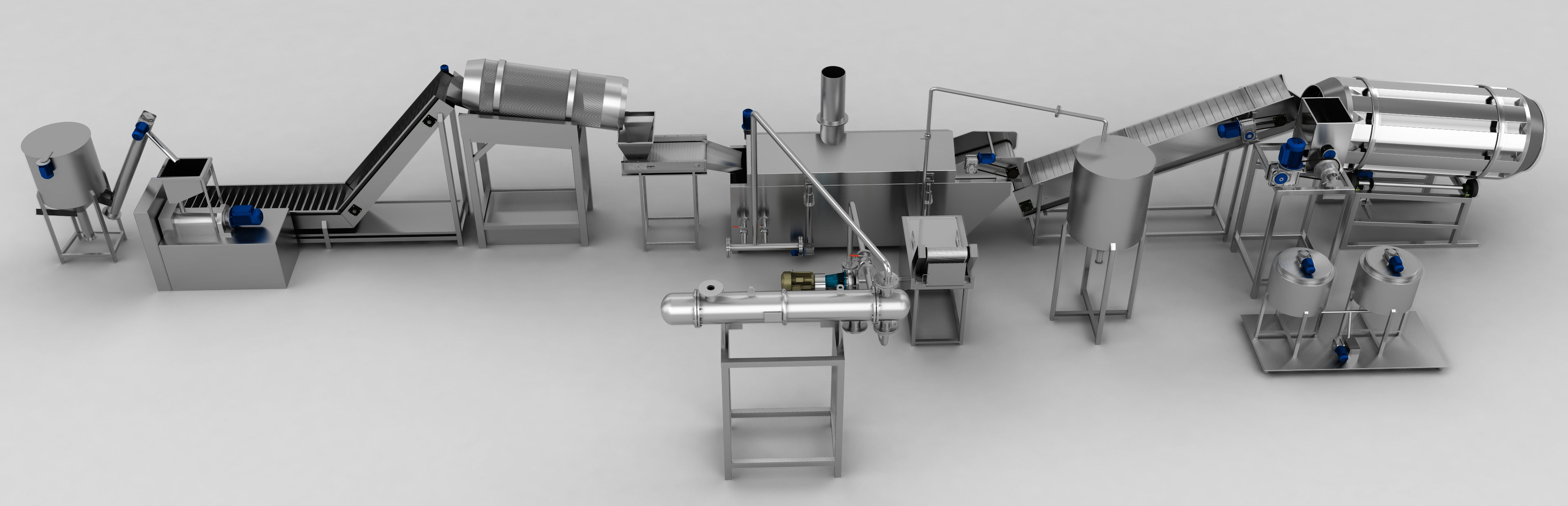

Kurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The kurkure meal (Raw Material) is moisturized in the flour mixer (Ribbon Blender) with water and fed to the rotary die extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passed through the die and gets cut by the cutting knifes into required lengths. The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste.

This Extruded snacks line mainlly consists of meal mixer, extruder, sifter, vibrating feeder, continuous fryer, de-oiling conveyer belt, seasoning, Slurry making tanks, cooling converyer.

Special Features

Specially engineered multi oil inlets maintain positive oil flow to clear the product infeed area & provide precise control of temperature & rapid adjustment to feed change.

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through drum filter to remove 100% product particles for the highest oil & product quality.

Low oil volume and rapid oil turnover assure fresh product with a long shelf life.

Indigenously developed air knife removes excess surface water from washed slices. Less pm-frying slice surface moisture reduces energy consumption & increases the edible oil self life.

Compact design results into cost efficient operations by reducing space, energy & water usage.

General Information

| Model |

200 Kg/Hr |

300 Kg/ Hr |

| Capacity | 200 Kg/hr. Ready fried and Seasoned Extruded Snacks | 300 Kg/hr. Ready fried and Seasoned Extruded Snacks |

| Man Power Required | 2 | 2 |

| Floor Space | 1200 Sq. Ft | 1400 Sq. Ft |

| Oil in system | 200 Ltrs | 300 Ltrs |

| Products | Corn Grit / Rice Grit / Gram Grit based Extruded Snacks | |

| Heating System | Diesel / Gas / Wood / Thermic Fluid / Pellets etc. | |

| MOC | AISI – SS- 304 Food Grade | |

Technical Specifications

| Model | 200 Kg/Hr | 300 Kg/ Hr | 500 Kg/Hr |

| Total connected load | 40 KW | 68 KW | 100 KW |

| Thermal Load | 1 Lac Kcal/hr. | 1.5 Lac Kcal/hr. | 2 Lac Kcal/hr. |

| Diesel | 5 liters per Hr. | 8 liters per Hr. | 10 liters per Hr. |

*Please note that 1 L Diesel = 1 Unit of Gas = 4 -5 Kg of Wood

With an experience of more than 35 years, we are constantly striving for the best possible out come for food and snack industry.

With an experience of more than 35 years, we are constantly striving for the best possible out come for food and snack industry.