Batch Based Pellets/ Fryums Production Line

Batch Based Pellets/ Fryums Production Line

In batch line, each step is done manually. We have different types of batch fryers for it. After frying, we have batch centrifugal dryers for de-oiling process. And when de-oiling is done, we move for flavoring, so for flavoring or seasoning, we have batch type seasoning system also. We have such environment-friendly 100-1500 Kg/ hr.

Special Features

Frying Control

Specially engineered multi oil inlets maintain positive oil flow to clear the product infeed area & provide precise control of temperature & rapid adjustment to feed change.

Continuous Filtration

Circulating oil keeps fines in suspension for efficient removal. Every minute 100% of the system oil volume passes through drum filter to remove 100% product particles for the highest oil & product quality.

Oil Quality

Low oil volume and rapid oil turnover assure fresh product with a long shelf life.

Air Knife

Indigenously developed air knife removes excess surface water from washed slices. Less pm-frying slice surface moisture reduces energy consumption & increases the edible oil self life.

Compact Design

Compact design results into cost efficient operations by reducing space, energy & water usage.

FRYER

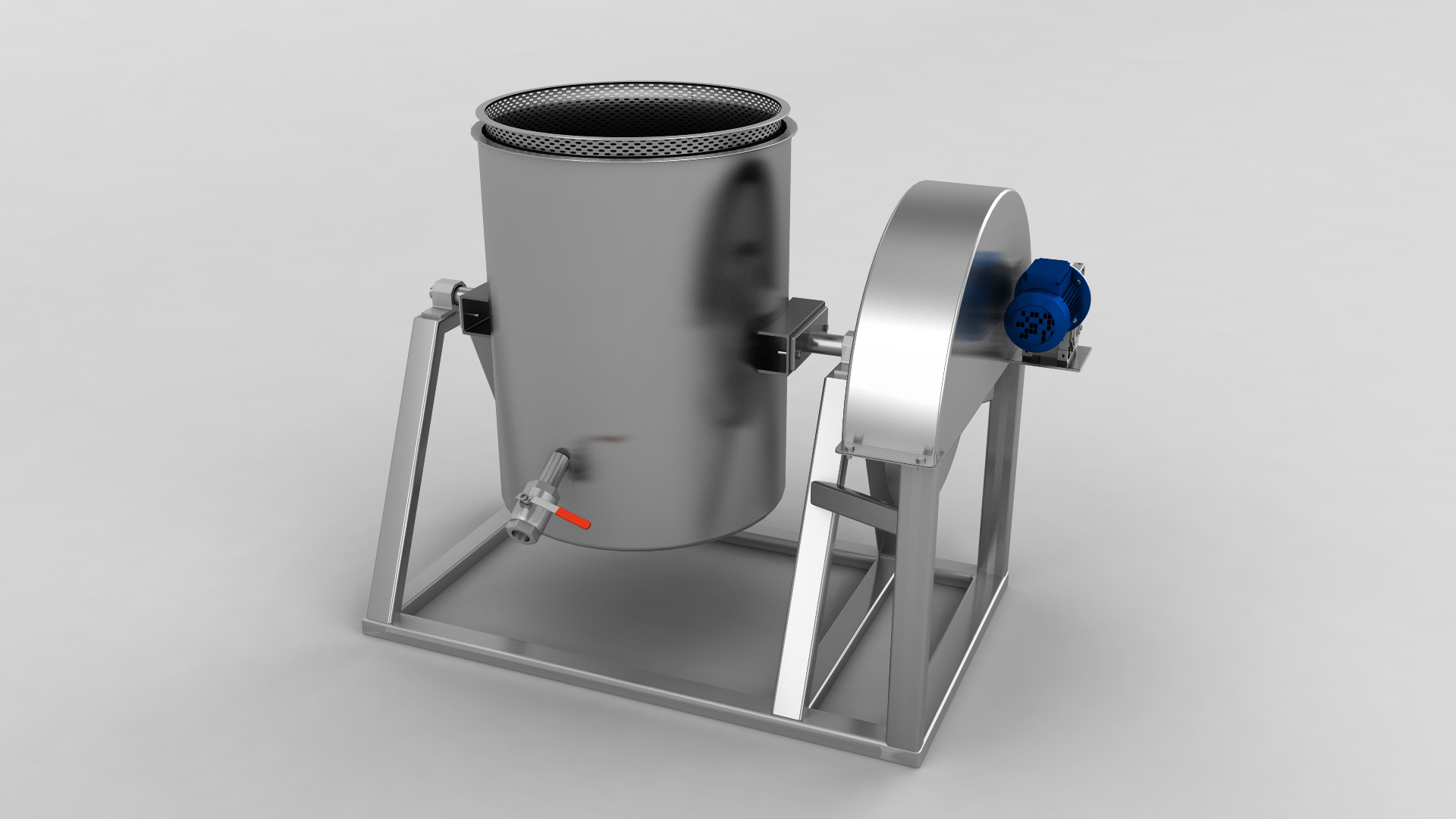

DRYER

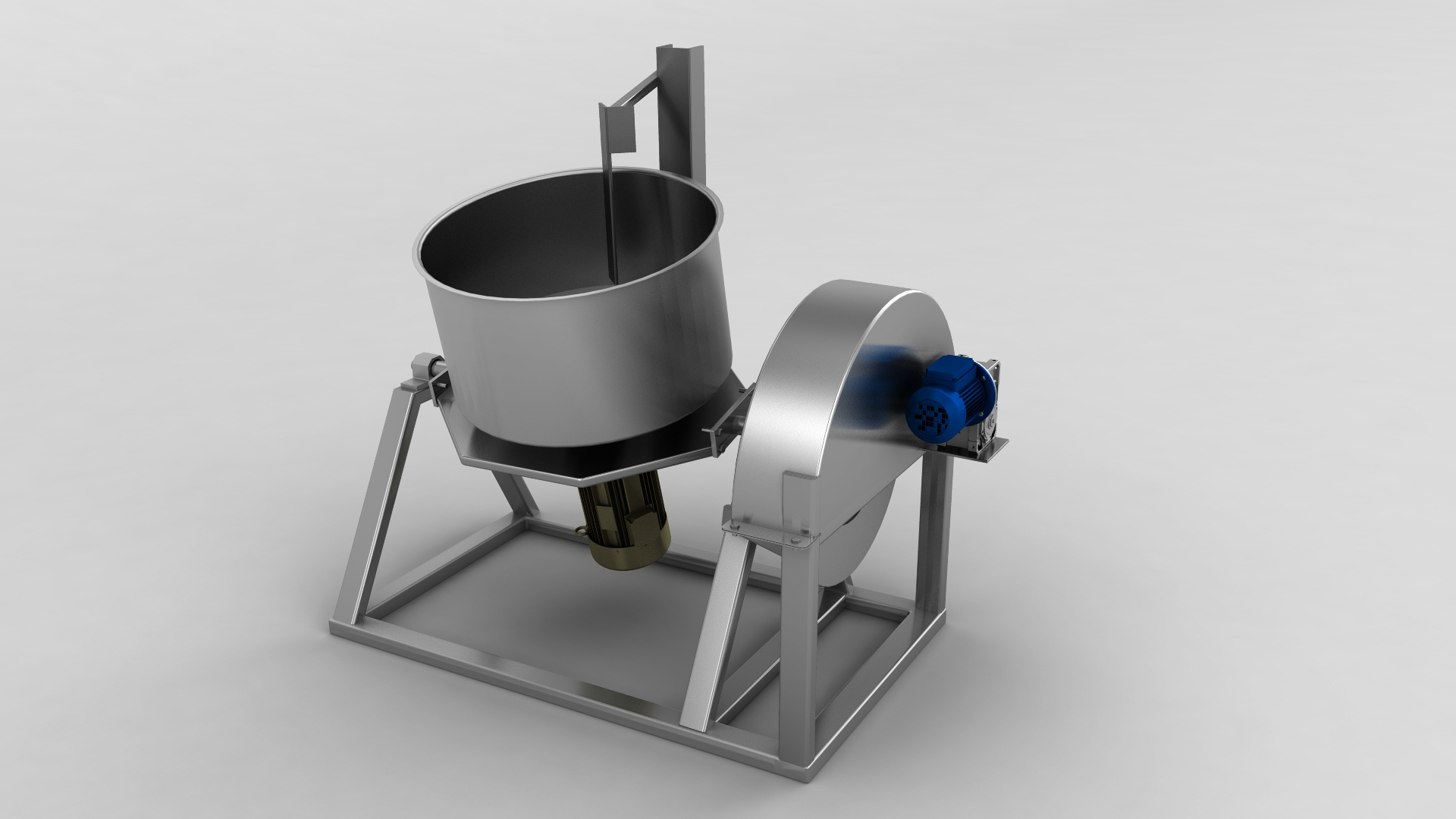

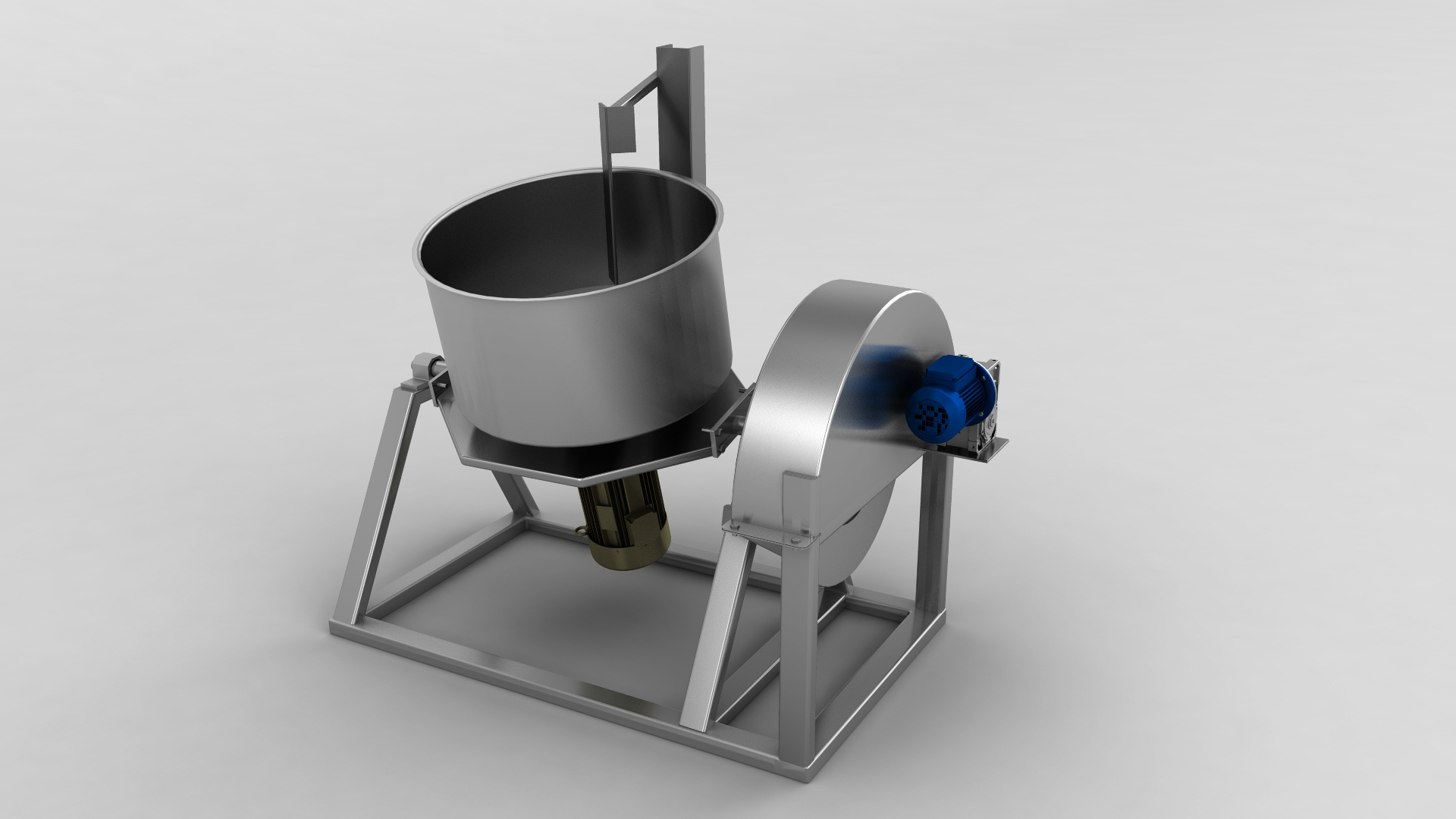

SEASONING

Fryer

In a Pellet production line, the fryer has a very important role, Dynamech engineers with a lot of research and experience have designed some of the very best fryers for the industry, totally customized and Utility based fryer has different technology and capacity as per the demand of the industry. In some cases, the same fryer can be used for the production of different production lines as well. The main objective of designing so much option is to just make to sure to a maximum of the return on investment for our valuable clients.

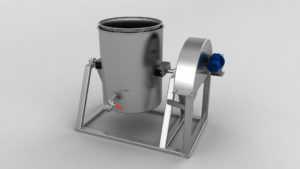

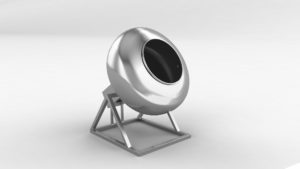

Dryer

Dynamech Engineers have immaculately designed Centrifugal Dryer Machine in view of the needs of the Snacks Industry. Centrifugal Dryers are used popularly for drying the namkeens and potato wafers. The product to be dried is placed in the rotating basket of the Dryer and allowed a few spins. The result is the surface water of the product is removed and not fully dried. Your snack intermediate is ready for further processing! Our centrifugal dryers have been designed with sturdiness and simplicity and are available at affordable prices.

| Centrifugal Dryer Tilting | ||

|---|---|---|

| Model | CDT 20 | CDT 30 |

| Production Capacity | 3 Kg/4mins | 5 Kg/4mins |

| Production Per Hour | 300 Kg/Hr | 450 Kg/Hr |

| Power Required | 1.5 H.P. | 2.5 H.P. |

| Centrifugal Dryer | ||

|---|---|---|

| Model | CD-05 | CD-10 |

| Size of Basket | 14″D x 12″H | 16″D x 16″H |

| Capacity Per Batch | 1 Kg / 3 mins | 1.5 Kg / 3 mins |

| Power Required | 0.5 H.P. | 1 H.P. |

Tilting

Non-Tilting

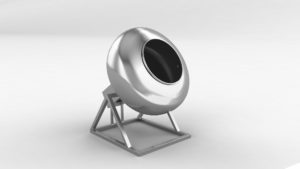

Coating/ Seasoning

Now apply any seasoning to your product with Dynamech Engineer’s Spice Coating Drum uniformly and add punch to your delicacies. Our Spice Coating Drums are designed in a manner in which your spices evenly mix with the Products. Made up of Non-Rusting Material, our spice mixers are durable and long-lasting. Our machines are also used for coating spices on products like Kurkure, Potato Chips, etc.

We offer these spice mixing machines at economical prices in variations of sizes shipped both in India and abroad!